CAPABILITIES

FEASIBILITY

Appraise, select and Techno economic studies

FEED

Provide the first class services in executed feed projects in Offshore, Onshore and Refineries

ADVANCE ANALYSIS

Highly reliable dynamic modeling nad machine learning solutions

PROJECT MANAGEMENT

Project execution strategy, project control and learned lesson management

MACHINE LEARNING

Full scale project, ML based Solutions to empower operating companies gaining more insights about their real facilities performance

COMPANY CAPABILITY AND EXPERTISE

Optimize Global Solutions capability to assist customers during all phases of Project Development, from preliminary Feasibility Studies and screening quality Cost Estimates through to Detailed Engineering Design including Asset Performance Management, Asset Integrity Management and Condition-based Management.

Optimize Global Solutions handles projects of all sizes from minor trouble-shooting exercises through to full Engineering support. It is particularly responsive to customer’s needs and operates as an extension to the Customer’s own organization. We recognize the need to balance cost versus “value add” to deliver a cost-effective solution to our customers

Optimize Global Solutions increasing capability has supported solid growth, particularly in the Hydrocarbons sector. Our growing team is assigned to perform work for various customers in the region and across Africa. The recruitment and expansion strategies at our location are focused upon providing the right people to meet the needs of our customers.

Optimize Global Solutions team prides itself in being able to provide total solutions to meet customer’s requirements. In brief, Optimize Global Solutions is supported by an array of state-of-the-art management, engineering and construction services that provide our customers a top performance project.

Optimize Global Solutions shall use the Full project management, project controls, procurement support, quality assurance, HSE management for all projects type.

Further discipline expertise exists in all engineering disciplines including Process engineering and process simulation and comply with equipment selection based on the customer requirements such as rotating and static mechanical equipment for design of pumps and tanks.

Optimize Global Solutions has a proven record of achievement, having successfully completed a wide range of projects in this region.

Optimize Global Solutions provides full engineering design and project management capabilities, covering the following areas:

- Onshore & Offshore facilities.

- Asset Performance Management.

- Asset Integrity Management.

- Pipeline Dynamic Assessment

- Compressor Dynamic Assessment.

- Refineries, Petrochemicals and Chemical Plants.

- Pumping stations & Depot Management.

- Renewable Energy and Green Ammonia Processing

FEASIBILITY

Machine Learning and Data Science

- Advanced and dynamic modeling using ML (Machine Learning) tools.

- Refinery Linear Programming for the best return of investment using GEKKO Dynamics.

- Applying Machine Learning algorithm on production facilities to improve and optimize the operating conditions and predict the potential downtime.

- Supporting the predictive maintenance via clustering and classification methods.

- Predict the failure of rotating equipment using logistic regression method.

PROCESS SAFETY

- Ability to conduct and lead HAZOP/ HAZID safety studies.

- Consequence modeling.

- Severity analysis.

- Risk Assessment.

- Dynamic QRA (Quantitative Risk Assessment).

- LOPA and SIL Determination.

- SIL Verification.

flow assurance

- Detailed thermal-hydraulic analysis.

- Sub-sea jumper thermal assessment.

- Production profile management and field life cycle evaluation.

- Hydrodynamic and terrain slug assessment.

- Hydrate Assessment & Remedy.

- Erosion-Corrosion Assessment.

Process Engineering

- Feasibility Studies and Techno-economic Evaluation.

- Project Evaluation and NPV (Net Present Value) Assessment.

- Field Trouble shooting and ad-hoc studies.

- Production increase and Real Time Optimization (RTO).

- Pressure surge (water hammer) analysis for pipeline and piping.

- Operator Training Simulation.

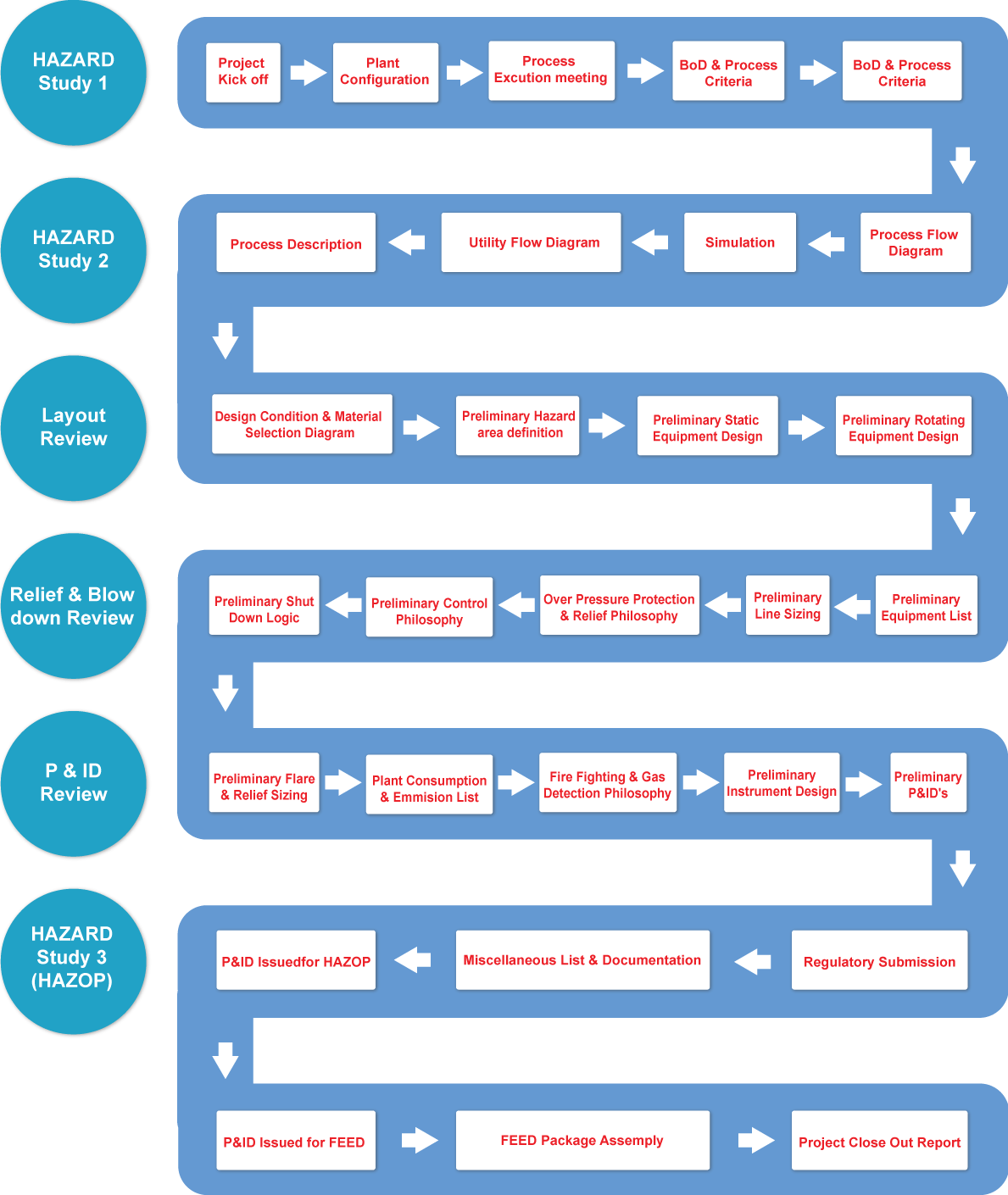

FRONTEND ENGINEERING DESIGN

Optimize Global Solutions ’s skilled and experienced professionals are dedicated to providing first class service in executing FEED project in offshore processing, upstream GOSP, gas processing and refinery engineering.

Our structured way of working has enabled and empowered us to execute various FEED projects over the last 5 years in Oil & Gas industry.

ADVANCED ANALYSIS

Optimize Global Solutions has the capabilities to technically evaluate field complexity and assist the customer to make right decision for the most viable engineering options. Our technical solutions include

- Dynamic analysis & optimization for oil & gas facilities.

- Pressure surge analysis for liquid pipelines and offshore pipework.

- Erosion-Corrosion assessment.

- Compressor surge analysis.

- Upstream lifecycle assessment.

- Process economic analysis and project evaluation.

Project Management

- Optimize Global Solutions supports the construction plans throughout the full lifecycle of the project to yield the greatest possible benefits to our customers.

- Optimize Global Solutions helps customers realize the maximum value of their project delivery by converting high-potential value options identified in the conceptual phase into fully defined, safe and successfully executed ones.

OTS

Operator Training Simulators (OTS) are advanced computer-based training tools that help give operators the skills they need to run a process or plant. Operators learn how to manage a refinery in this virtual computer through the use of dynamic simulation model that controls the plant responses. This provides trainees the opportunity to learn how to react appropriately when a similar situation occurs in the actual plant. The use of Optimize Global Solutions OTS solutions enables companies to address challenges before they occur in the real world, which helps them remain competitive in the global economy.Functions included in OTS are as follows:

Reduce Startup and Commissioning Times

Operator Training Simulators effectively train operators for controls checkout and plant startup to reduce commissioning times significantly. These systems help ensure faster startup times, quicker recovery from process upsets, fewer equipment stresses, and the ability to correct procedure errors prior to online production.

Reduce Startup and Commissioning Times

Operator Training Simulators effectively train operators for controls checkout and plant startup to reduce commissioning times significantly. These systems help ensure faster startup times, quicker recovery from process upsets, fewer equipment stresses, and the ability to correct procedure errors prior to online production.

SOFTWARE LIST

- HYSYS Steady State

- HYSYS Dynamics™

- PROII

- Aspen EDR

- Aspen Custom Modeler

- Hysys Refinery™

- OLGA

- Pipenet

- DNV GL Phast

- Pipephase

- Autocad

- Aspen Flarenet