Optimize Global Solutions provides consulting services to help companies to reduce the likelihood and consequences of release events, ensure operation stability and increase the profit margins. Our engineering services enable our clients to achieve their safety and security objectives more efficiently and effectively.

Engineering Services

Process Safety and HSE

Project Management

Facilities Management

SERVICES

Optimize Global Solutions provides consulting services to help companies to reduce the likelihood and consequences of release events, ensure operation stability and increase the profit margins. Our engineering services enable our clients to achieve their safety and security objectives more efficiently and effectively.

Optimize Global Solutions can offer full discipline engineering services including:

ENGINEERING SERVICES

MACHINE LEARNING AND DATA ANALYTICS

Optimize Global Solutions has the capabilities to provide an integrated ML (Machine Learning) solutions. This bilateral cooperation entails data analytics, developing predictive models, deep learning and apply machine learning methods in oil and gas industry.

- Advanced and dynamic modeling using ML (Machine Learning) tools.

- Refinery Linear Programming for the best return of investment using GEKKO Dynamics

- Applying Machine Learning algorithm on production facilities to improve and optimize the operating conditions and predict the potential downtime.

- Supporting the predictive maintenance via clustering and classification methods.

- Predict the failure of rotating equipment using logistic regression method.

PROCESS MODELING AND ADVANCED ANALYSIS

UPSTREAM WELLS MANAGEMENT

- Multiphase flow for well shut it condition modeling.

- Piping transient analysis for pressure surge and un-balanced forces.

- Field lifecycle and integrated asset model.

PIPELINES

- Pipeline dynamic modeling as start-up, shutdown, cool down, pigging and depressurization.

- Pressure surge assessment for Pipeline.

GAS GATHERING STATIONS & GAS PROCESSING PLANTS

- Steady state simulation and flowsheet optimization.

- What-if scenarios and case studies.

- Energy optimization for Pinch technology assessment and heat exchanger network optimization.

- Rigorous thermal rating of TEMA-type exchanger.

- Dynamic studies for start-up, shutdown and abnormal assessment.

- Process Economic Analyzer for project economic evaluation.

- Blowdown assessment for adiabatic and non-adiabatic (fire) depressurization.

REFINERY UNITS: MODELING & OPTIMIZATION FOR THE FOLLOWING UNIT OPERATION.

- Vacuum tower and heat integration.

- Crude distillation column optimization.

- Fluid catalytic cracking modeling, tuning and optimization.

- Delayed Coker modeling.

- Visbreaker modeling.

- Naphtha hydrotreater modeling.

- Preheat train modeling.

ADVANCED ANALYSIS GROUP WITHIN OPTIMIZE ENGINEERING CAN SUPPORT AND PROVIDE THE FOLLOWING DOMAINS

- Anti-surge compressor modeling.

- Hydrodynamic analysis for distillation column.

- Pressure surge assessment and surge mitigation.

- Weightage score for options assessment and option selection.

- Quantitative Risk Assessment.

- Computation Fluid Dynamics.

- Reservoir to Facilities ™.

- Integrated Asset Modeling ™.

- Economics ™.

PROCESS SAFETY MANAGEMENT & HSE

Optimize Global Solutions Engineering provides consulting services to help companies that use hazardous materials to reduce the likelihood and consequences of release events. Our services and products enable our clients to achieve their risk, safety and security objectives more efficiently and effectively.

- PHA.

- HAZOP and HAZID Safety Studies.

- Process Safety Management.

- Risk Management Plan.

- Bow-Tie Analysis.

- Consequence Modeling.

- Probability Modeling.

- Facilities Siting.

- Layers of Protection Analysis (LOPA).

PROJECT MANAGEMENT

Our team is committed to:

- Provide any unique combination of services to suit our Client’s requirements.

- Applying best practices, based on the Project Management Body of Knowledge (PMBOK).

- Understanding our Client’s value chain, systems and procedures, thus enabling us to manage and mitigate risk on any given project, irrespective of the drive behind the project (e.g. legislative reasons, economic gain or strategic value).

- Striving to set new benchmarks through innovation.

Optimize Global Solutions through proper project management control pays specific attention to integrating all project management sectors. By sectors we are referring to:

- Overall project management.

- Project administration.

- Engineering Design.

- Contract interface management.

FACILITIES MANAGEMENT

Facilities management is a holistic approach to develop performance, integrity and maintenance strategy with an aim of optimizing the operation. Also known as PIMS (Performance Integrity Maintenance Management System).

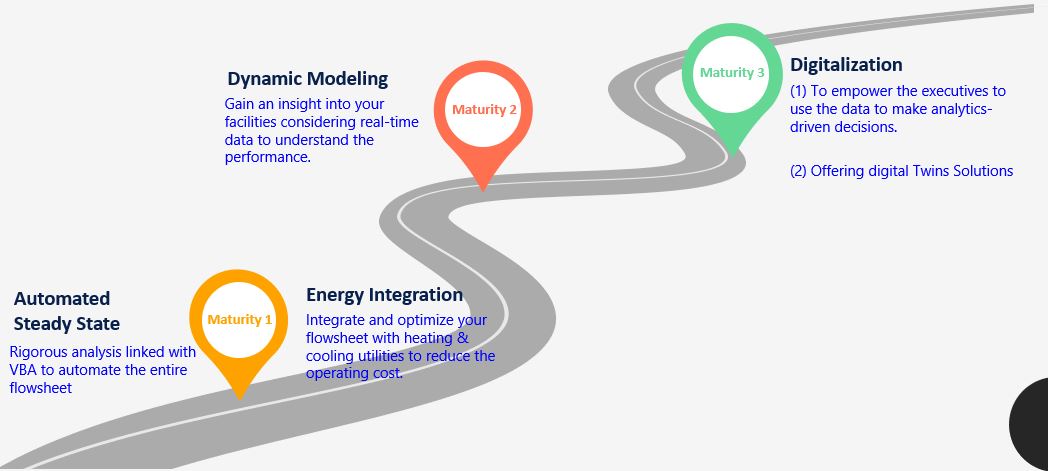

Performance Management

Energy optimization and cost-benefit analysis oriented and in comprises three level of maturations.

Integrity Management

We provide an asset integrity studies in compliance with API 579 including level1, level2 and level 3. In addition, piping excitation analysis is included under the asset integrity plan to avoid the vibration induced fatigue failures.

Condition-based Management

Under condition-based management, we offer risk-based inspection techniques in compliance with API 851 to determine the strategy of the maintenance. More importantly, the predictive maintenance plan is utilizing machine learning to estimate the remaining useful life of your rotating machine.