Dynamic Nodal Analysis- From Reservoir to Facilities

Introduction

Engineering teams face a number of challenges while recovering fields and increasing capacity. Promoting integration and communication between disciplines is very useful to properly assess the performance of process facilities under normal and abnormal operation and, most importantly, to avoid the risk of unnecessary costs.

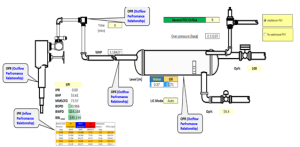

The traditional approach is basically to assess and model each domain separately, and the reservoir results need to be fed into the flowline domain and process facilities. This workflow primarily resulted in a key problem process simulator that only represents a point in time which in turn fails to update the process modeling if the reservoir performance changes. Due to the increased awareness and maturity level in the engineering company, the IAM (Integrated Asset Modeling) concept started to dominate the upstream industry and flow assurance assessment such as the PIPESIM and MAXIMUS application.

Be that as it may, the latter two software are limited in process equipment and transient analysis. This article mainly focuses on using HYSYS Dynamics together with VBA to build the reservoir model and its flow performance relationship and accurately predict the production of gas, oil and water in response to downhole pressure change due to events. abnormalities that may occur on the surface of the premises.

First Principles Concept

IPR: Inlet performance ratio or IPR is defined as the functional relationship between production rate and bottom orifice flow pressure.

OPR: Production system components that are downstream of the selected node are included in the outflow sections. The main components of an outflow section are:

- Production piping.

- Good head.

- Strangle.

- Flow line.

- separator.

A comprehensive understanding of all these components is required when building outflow performance curves.

Technical Discussion

Steady-State Approach : Based on the Steady-State HMB, the analysis considered the total flow from the production manifold without considering the actual reservoir performance using the HEM method.

The HEM method under the steady state approach reported an orifice area requirement of 119.63 cm², which is much more than the existing orifice area. To satisfy requirements, the system must employ two (2) extra T-holes in addition to the existing PSV T-hole.

Dynamic Nodal Analysis Approach : The relationship between bottom orifice pressure and reservoir output was considered in the dynamics to assess the suitability of the existing T-orifice PSV against the total blocked outlet box. It was found that the transient pressure rise exceeded the allowable overpressure of 15.18 barg and reached 20.4 barg.

A sensitivity case was performed considering various orifice sizes for additional PSV, to determine the proper size to avoid an overpressure case. The results of the tested orifice sensitivity case were plotted in the following figure to demonstrate the transient pressure rise. It is evident from the above results that the proposed orifice Q is not suitable where the transient pressure exceeds the MAWP of the vessel, while the orifice R is considered suitable. Given the mathematical link between the behavior of surface installations and the IPR (Inflow Performance Relationship) of the reservoir, the blocked outlet case had a detrimental impact on the production profile where production rates declined.

Load Relief Modeling

Relief loads for the existing PSV (orifice T) and the proposed PSV (orifice R) are shown below. The blue dotted area demonstrates an overflow in the gas and oil relief flow. This transient behavior is attributed to the water level rising for almost eight (8) minutes.

During the rising water, the accumulated volume inside the three-phase separator that contains oil and gas is continuously compacted due to the expansive thrust of the rising water. By the time the gas pressure reaches the set point, the rate of relief is proportionally dependent on the driving force (∆P = pressure relief-back pressure flare) and in inverse proportion to the resistance (i.e., orifice area ). In principle, the following rule governs the case. Rate α (Motive force / resistance).

When the water level reaches the gas outlet, the system will reach regularization conditions. In the liquidation condition, the corresponding relief loads of the existing T PSV hole + R PSV orifice are as follows:

- Q gas = 61.1 MMSCFD

- Q oil = 25,065 bbl/d

- Qw = 80,471 bbl/d

For more details about the Dynamic Nodal Analysis concept, read the whole article in below link.

https://pt.processindustryinformer.com/dynamic-nodal-analysis

Leave a Reply